The Early Days…

Coronium’s long involvement in the solar industry dates back to 1990. It was the pioneering projects and the range of applications that attracted us as young engineers to the solar industry. Our jobs took us to all corners of the globe and to the some of the remotest communities you could imagine.

We also had the opportunity to visit several of the leading overseas solar module manufacturers who produced the highest power solar modules available at the time - a maximum power of 50W and with pricing around USD10.00/Wp!

Our passion today is as strong as ever, and we would like to share some of the “early days” with you, long before Standards and Accreditation became part of our everyday lives!

Off-Grid Solar

Back in the late 70’s and through to the early 90’s, the cost of solar modules was extremely high. However, they provided a power solution in a variety of applications where they made both financial and operational sense.

Telecommunications

In Australia, Telecom Australia (now Telstra) was the first organisation to use solar technology on a larger scale. It recognised the potential of utilising photovoltaics to supply power to many of its outback telecommunication systems. They started working with the two local manufacturers BP Solar and Solarex to ensure system reliability. Field testing feedback and established environmental test facilities helped to deliver products that could withstand the harsh Australian conditions for over 30 years - many of which are still working today.

Today, Telstra still use solar and battery storage technology as the primary way of supplying power for their remotely located equipment.

Overseas, hybrid solar power was often used to support the telecommunication backbones of developing counties. The projects we were involved with took us to Cambodia, China, India, Indonesia, Fiji, Malaysia, PNG, Thailand and Vietnam.

Industrial

Solar found its way into several industrial applications across the Australian mainland and its oceans, including signboard lighting, rail signalling, cathodic protection systems for gas pipelines, ground stations for air services, fire watch towers, and oil platform and tower navigation lights.

Community Development Programs

During the 90’s there were several Government assisted programs which supported the electrification of communities in third world countries particularly in Malaysia, Philippines, Sri Lanka and the Pacific Islands – providing solar electricity to people who had no chance of ever being connected to grid electricity.

These projects became exciting programs, resulting in the mass deployment of small solar and battery systems for domestic and village lighting, schools, water pumping and powering vaccine refrigerators. Key to the success of these and similar programs is engaging with the local communities, ensuring their involvement and providing training so the communities can take ownership and have the responsibility to care for their solar systems.

Among the key challenges was often logistics and getting equipment to site - a long trek through the jungle with porters carrying the equipment, or even transfer by small boat to the many islands off the mainland.

On-Grid Solar

Towards the mid to latter 1990’s, we began connecting the first solar inverters to the grid. If you think obtaining permission to connect to the grid is somewhat difficult today, you should have seen what it was like to connect a 1kW inverter back then. The networks were extremely nervous about the disruption that it would cause, and without any regulatory framework, standards or sophisticated electronics and protection devices available, it made for obtaining approval an unpredictable challenge.

Small Scale (<100kW)

On the residential front, the Athletes Village for the Sydney 2000 Olympic Games was the first real example of a roll-out of grid connected solar in a cluster area. A total of 665 systems each of 1kW were connected in Newington, and they are still in operation today.

Post the year 2000 we saw the first small scale commercial scale solar systems deployed, including individual installations such as on service stations, markets and corporate enterprise, or installations under programs like Solar Cities, Solar Schools and the Building Education Revolution (BER).

Medium Scale (<1MW)

Until this point, Australia was always one of the world leaders in solar, both from a technology and implementation point of view. However, Australia was very slow to connect larger capacity systems, with Europe, the United States and Asia taking the lead in this domain.

In order to stay in front, our focus had to move off-shore, and from 2004 we commenced delivering grid-connected projects in both China and South Korea.

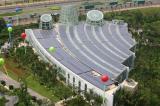

There has been so many satisfying projects! Two early standouts are the implementation of China’s first 1MW project in Shenzhen, and the construction of the iconic Solar Sail in Guangzhou.

Large Scale (> 1MW)

Check out our Large Scale Solar story here.

Manufacturing of Solar Cells and Modules

Coronium’s experience in cell and module production also dates back to 1990.

Australia

Tideland was the original solar cell and module manufacturer based in Brookvale, before being acquired by BP to form BP Solar. Solarex, located in Villawood was the other supplier, with the two companies merging in 2000 and relocating to Homebush Bay.

While the Brookvale facility was almost completely a manual operation, the new factory at Homebush Bay was semi-automated.

We worked hand in hand with the factory, because in those days there were only a handful of standard products, and usually the projects we were implementing required solar modules that were custom made products that required specific testing regimes.

China

In 2004, BP Solar formed a JV with Chinese company SunOasis, based in Xian.

Over the next two years, we were extensively involved in raising the quality of product produced from the Chinese factory to meet tough international standards, transferring technology and know-how from the Australian plant, while at the same time expanding the production facility.

This period gave us a deep understanding of the intricacies of module manufacture - vital knowledge that Coronium uses today when selecting third party Tier 1 modules that are going to have to perform for 25 years plus.